The material of the future is likely to be in forest waste from Peruvian Amazon

Síguenos en:Google News

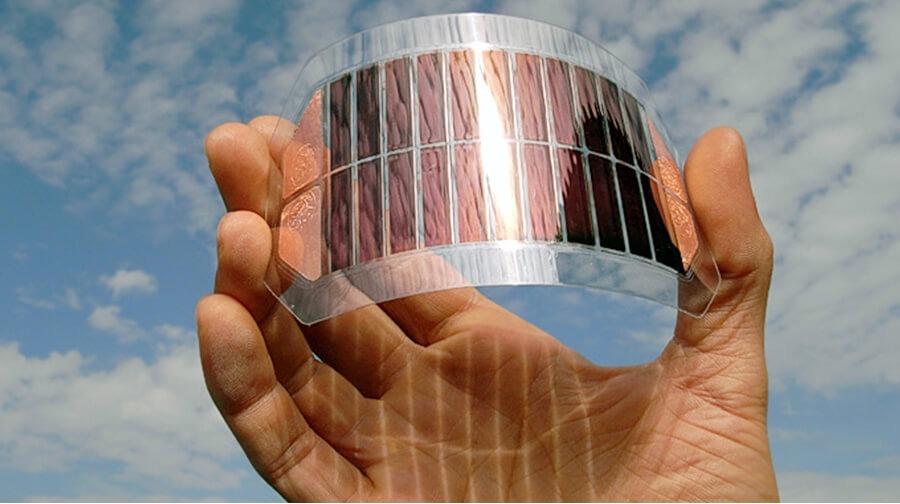

Stronger than steel and lighter than aluminum, this is graphene, a material considered to be the material of the future and which is expected to be made soon with forest waste from the Peruvian Amazon. This is thanks to the project being developed by researchers from the Pontifical Catholic University of Peru (PUCP), with funding from the National Council for Science Technology and Technological Innovation (Concytec).

Also known as "God's material", graphene is a carbon product that is very similar to a black powder, and whose essential characteristic lies in the order of its atoms, which gives unusual properties to the resulting material. Although carbon is the second most widespread element in nature (hydrogen tops the list), isolating it in its purest form for the production of graphene was for many years considered to be a challenge for many researchers.

Among the main properties of graphene are its strength and the fact that it can be used to manufacture electronic devices, according to Omar Troncoso, mechanical engineer from the PUCP and PhD in Chemistry from the University of Valencia, who is leading this project.

"Graphene combined with other materials can offer new properties, it could be used to make cell phone batteries lighter and more flexible, even for cars. It also aims to develop more flexible Smartphone and Smart TV screens", says Troncoso.

Teamwork

Together with the National Amazonian University of Madre de Dios (Unamad), the researchers are seeking to find different manufacturing methods, using the various raw materials offered by the jungle. To do this, they are trying to draw up an inventory as a first step, by locating the sources of forest waste such as sawdust from wood or chestnut shells. Secondly, these materials will be processed to obtain a source of pure carbon; and finally, the necessary processes will be applied to obtain the graphene.

"We aim to obtain graphene that is similar to commercial graphene, the purest form. This should ideally have the thickness of one atom, but it is difficult to obtain it in the laboratory. A more economical and viable alternative is to produce graphene oxide, which, although it is not one atom thick, does have a thickness that is similar to pure graphene. The oxide is therefore reduced to make it as close to graphene as possible," explains Omar Troncoso.

Troncoso also added that part of the aim in this project is to produce graphene of the same quality as in other countries and to market it in laboratories in the United States and Europe. "There is a graphene market, it is sold to laboratories and companies undertaking innovation projects; they buy it and do not manufacture it. We bought an envelope from a laboratory in the United States to study it, and a gram costs about $1,000.

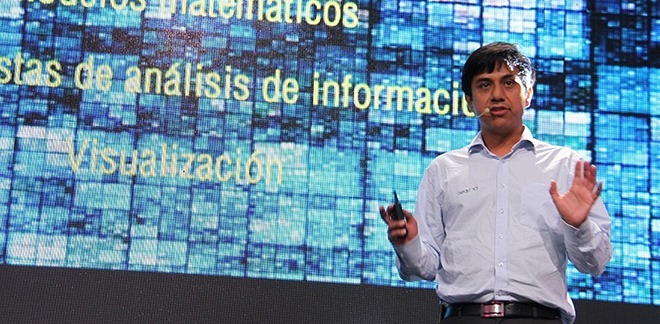

Innovative group

This project is headed by the Polymers and Composites Research Group (Polycom) at the Mechanical Engineering Faculty of the PUCP, who received a grant of S/ 350 thousand, the list consisting of 190 projects from 20 regions in the country, winners of the 2018 Applied Research and Technological Development Projects Competition held by CONCYTEC in agreement with the World Bank (WB).

The team is formed by Omar Troncoso, Fernando Torres and Liset Rodríguez; the latter being a chemistry researcher from the National Amazonian University of Madre de Dios.

Did you know?

- The Guardia reported that Samsung is investing millions in research for graphene-based products to be on the market in the next five years.

- According to a study conducted by the Coal Biomass Research Group (PUCP) in 2013, Peru generates 10 million tons of residual biomass from agro-industrial activity, agriculture and the timber industry. These residues are potentially the raw material to make graphene.

Sources: Andina / Concytec / La República